Inside the Heart of Power: How Modern Car Engines Work and What Makes Them So Efficient

May 18, 2025

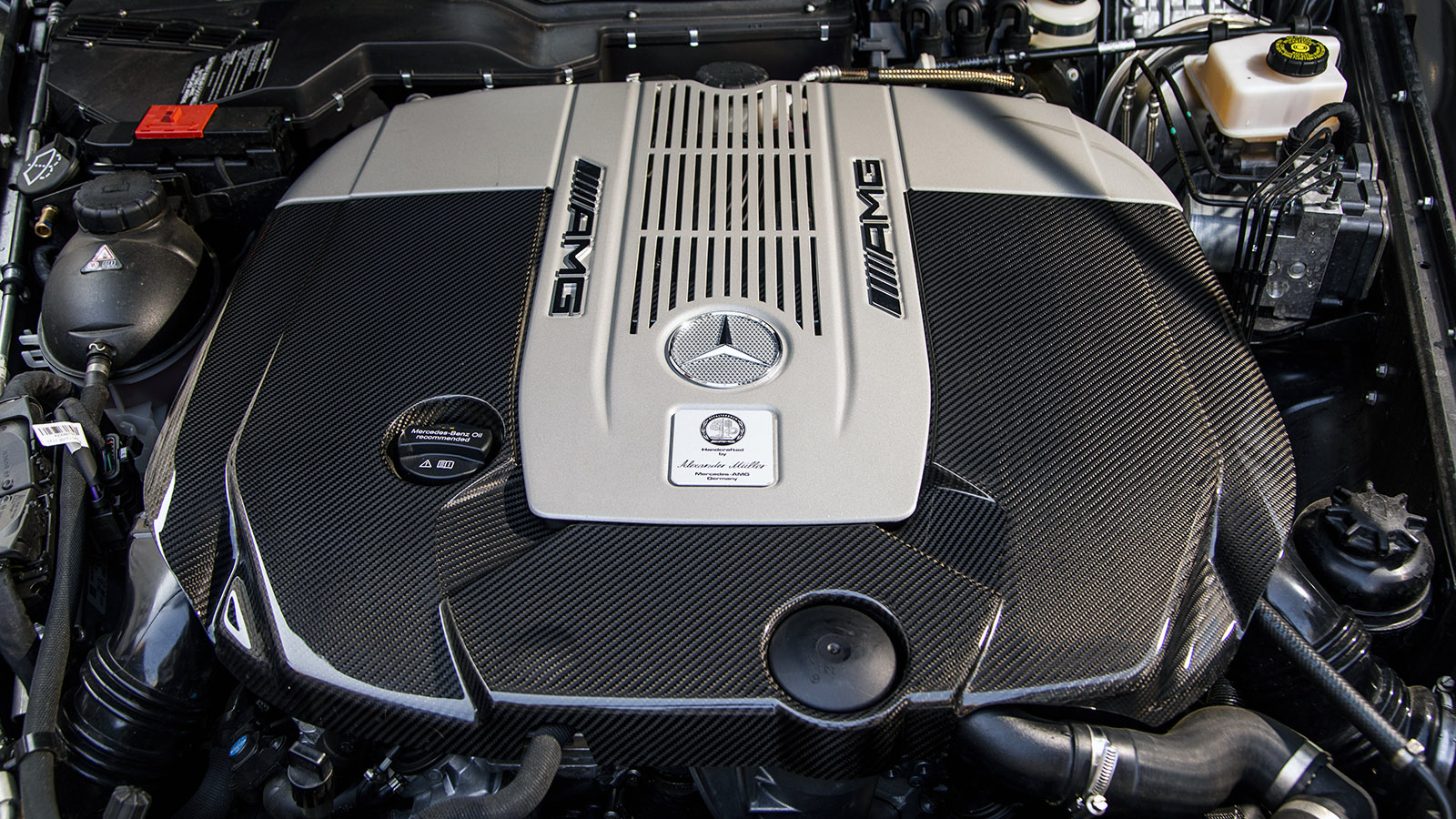

In the world of automotive engineering, the car engine is the masterpiece that defines the very essence of performance, efficiency, and reliability. While many people drive cars every day, few truly understand what goes on beneath the hood. Today’s engines are marvels of precision engineering, computer control, and mechanical innovation. They have evolved to become more powerful and more fuel-efficient than ever before, while also meeting strict environmental standards.

Let’s take a deep dive into the anatomy of a modern engine, how it works, and the advanced technologies that make it so remarkably efficient.

1. The Basic Principle – Internal Combustion

At its core, a car engine is a heat machine. It converts the chemical energy of fuel (gasoline or diesel) into mechanical energy that moves the car. This happens through a process called internal combustion, where a mixture of air and fuel is ignited inside the engine’s cylinders, pushing pistons down and turning the crankshaft. This rotational energy is then sent to the wheels.

Most modern engines follow a four-stroke cycle:

Intake: Air and fuel enter the cylinder.

Compression: The piston compresses the mixture.

Power (Combustion): A spark plug ignites the fuel-air mix.

Exhaust: Burned gases are expelled.

2. Precision Engineering – The Key Components

Every part of a modern engine is engineered for performance, longevity, and balance.

Pistons and Cylinders: These components must withstand extreme pressure and heat.

Crankshaft: Converts vertical piston movement into rotational energy.

Camshaft and Valves: Control the opening and closing of air intake and exhaust.

Timing Belt/Chain: Synchronizes the movement of engine parts.

Oil and Cooling Systems: Ensure the engine operates smoothly and doesn’t overheat.

3. Fuel Injection and Air Management

Older engines used carburetors, but modern engines rely on electronic fuel injection (EFI). This system sprays a precise amount of fuel into the intake manifold or directly into the combustion chamber.

Meanwhile, air intake systems use sensors to monitor airflow. Throttle bodies, mass air flow (MAF) sensors, and manifold absolute pressure (MAP) sensors all work together with the engine’s ECU to adjust the air-fuel mixture in real time for optimal performance.

4. Turbocharging and Supercharging – Boosting Efficiency

To squeeze out more power from smaller engines, manufacturers use turbochargers and superchargers.

A turbocharger uses exhaust gases to spin a turbine, forcing more air into the engine.

A supercharger is mechanically driven by the engine itself, offering instant power boosts.

These devices improve power-to-weight ratio and fuel efficiency, which is why turbocharged engines are now common even in small family cars.

5. Variable Valve Timing – Smarter Breathing

Systems like VVT (Variable Valve Timing) or VTEC (from Honda) allow the engine to alter valve operation based on RPM and load. This helps the engine breathe more efficiently at all speeds, boosting performance when needed and conserving fuel when cruising.

6. Direct Injection and Cylinder Deactivation

Direct fuel injection delivers fuel straight into the combustion chamber, improving power and reducing emissions. Some engines also have cylinder deactivation, where unused cylinders are temporarily shut off during light driving to save fuel.

These innovations are key to downsizing engines—making them smaller but more efficient and just as powerful.

7. Engine Management Systems – The ECU Brain

At the heart of every modern engine is an ECU (Engine Control Unit). This small computer receives data from dozens of sensors—temperature, oxygen, throttle position, engine knock, etc.—and constantly adjusts spark timing, fuel injection, and even valve operation. Without the ECU, modern engines simply wouldn’t function as cleanly or efficiently.

8. Emissions Technology – Clean Power

Modern engines include catalytic converters, exhaust gas recirculation (EGR), particulate filters, and sometimes AdBlue (for diesels) to meet global emissions standards. These systems ensure that even powerful engines produce minimal pollutants.

9. Maintenance and Lifespan – The Engine’s Longevity

Thanks to better materials, synthetic oils, and digital monitoring, today’s engines can easily exceed 300,000 km if properly maintained. Key maintenance tasks include:

Regular oil and filter changes

Replacing timing belts/chains at recommended intervals

Using quality fuel and spark plugs

Keeping sensors clean and functional

10. Conclusion – Small, Smart, and Strong

Modern car engines are no longer just about brute force. They’re designed to balance power, efficiency, and emissions, and they do it with the help of digital intelligence, advanced materials, and precision design. Whether you're driving a turbocharged 3-cylinder or a high-performance V6 hybrid, today’s engines are smarter, cleaner, and more capable than anything that came before.

As car technology continues to evolve, engines will become even more refined, incorporating AI, machine learning, and possibly even self-healing capabilities.